The joint company that manufactures olive processing machines in Mersin has developed an “olive color sorting machine”, which is evaluated in the world with a four-year similar work, but cannot be imported because it is expensive. Inovamer Makine, which was opened by Hayati Aslan in 2010 in the machine construction sector, which he entered from his childhood, has become a company that sells olive (olive color sorting machine) technology to 20 countries in the meantime.

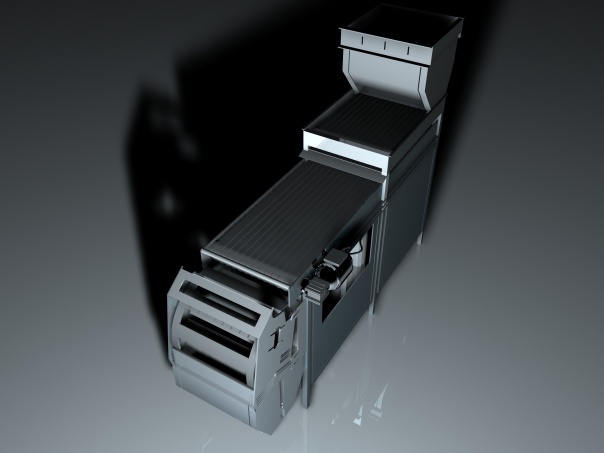

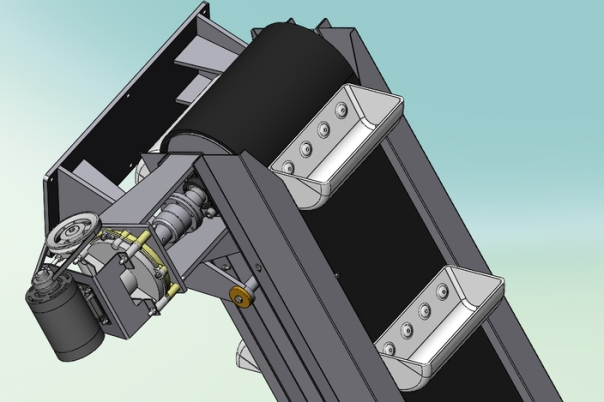

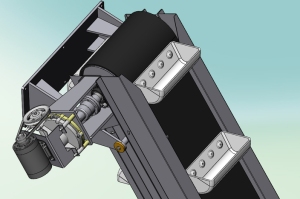

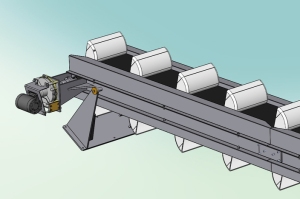

first fully automatic olive kernel extraction machine manufactures father Nazmi in Turkey the Lions, he took over the flag as general manager of the company Inovasi Machine General Director Yalcin Okatan in röpötaj made a star TV journalist, a 4-year deal with the first time in Turkey “olive color He said that they developed a selection machine. Aslan stated that the process of dividing green and black pieces from each other in vigorous and pickled olives was made by a significant majority of the Turkish olive producers because the machine made abroad in this square was too expensive, and in line with the request of the producers, a team of 10 people and completely special designs with a work of four years. He stated that they succeeded in making the local “olive color selection machine”. Aslan explained that the machine, which consists of the camera system of the olive color selection machine and the mechanism that transfers the olives to other channels by blowing air, can make a flawless distinction close to the work that 40 people work by hand in 1 day, and said that the machine they made provides an important advantage to the olive producer. Pointing out that the product collected from the olive branch should be processed on the same day, Aslan stated that if the olive color sorting machine they made is purchased from abroad, it is much more accessible than its counterparts with a cost of 95 thousand Euros. They sell the tools they produce to twenty countries Aslan, explaining that there are around a hundred machines needed by the olive industry such as olive seed sorting, slicing, stalk cleaning, screening, scratching and cutting machines, separating bands as well as the olive color selection machine they recently developed, He said that they exported to 20 countries including the Mediterranean countries such as Morocco, Tunisia, Algeria and Greece and the USA.

olive color separation machine sector in Turkey, indicating that the Lion last year in increased funding opportunities with very fast one way arrival, expressed as follows: “As long as the financing is no olive color sorting machines will üreteil in Turkey. 10 years ago, 20 years ago, the conditions in the country were different. that period we would have this desire to develop machines that we use on some parts we could find in Turkey, was the more difficult to get. Because reaching the world was more difficult. With the development of all these and the presence of money, the sector has rapidly increased. We have our minds, skills, manpower, and when there is financing, why not do it. ”MERSİN – Being the only company that received the Techno Entrepreneurship Support given by the Ministry of Industry from Mersin, Inovamer Information Technologies is preparing to produce an olive color selection machine. diseases will be eliminated with the sensitivity of an optical eye, while more olives will be delivered to the table. One of the most important features of the system is that it will deliver olives and olive oil to tables at more affordable prices as labor costs will decrease. After the investments to be made, the production of olive color sorting machine will start next year. purchased these products is Inovasi the first company to produce in Turkey, patents completes its work and product registered by the Ministry of ettirdi.sana Techno Venture Support explaining that given support under the Program Inovasi the Information Technology General Manager Hayati Lion, advanced technology products that support the olive color separation machine project He guessed that he bought it. Leo made in Turkey, indicating that the national production of one crop, “made in Italy and in the world, only Japan. just outside yu taken by the Union of Marmara in Turkey, because prices are much above “, he said. Stating that the product is sold in the sector for about one hundred and fifty thousand Euros, Aslan stated that as a company, they will spread that product to the market for half the price after production. Stating that they started to receive demand before the crop is on the market, Aslan said that they will start production next year according to the project’s business plan.

Explaining that they started R & D studies on the subject before establishing the company, Aslan said, “Olive color selection machine, Keeping the pulse of the market to develop new products and technology, understanding what the consumer wants, following the developments in the world and working with universities is of great importance. R&D work has now become a lifestyle for companies. We do all our dealings with a serious adrenaline and balance. We also take great pleasure in our achievements that have come as a result of very intense work ”. Emphasizing that it is necessary to increase the competitiveness in the field for a sustainable economy, Hayati Aslan said, “This can be possible by increasing R&D activities. If a newly established company does not have high capital power, it should conduct scientific studies and produce innovations in order to compete in the market with the biggest rooted corporate companies and to reach an advantageous position in the market. We base with olive color separation machine we are doing strong work, and I believe seriously that we will be with companies in the same category, “he said explaining that in the first five land area in that the manufacturing takes place between Turkey and the country is a world leader in olive target recognition processing konuştu.görünt vital Lion, He told the following information: “Olive can be damaged when plucked from the branch, or the sun side can be black and the side that cannot see can be green or purple. After those products are collected, they are slid on wide belts and damaged or different colored products are selected manually by people. This brings with it a significant labor cost and crop damage. The buyer company wants to buy quality products, so Olive color pick machine is needed. With the vehicle we have developed with our team of 10 people and started to produce, the costs will be reduced on the one hand and the number of usable crops will increase significantly on the other. be. We want to be a world-renowned brand in determining crop damage. image processing market in Turkey (Olive color separation machine) can say almost none. However, the area is too large as it enables the elimination of faulty crops. ”Planning investment in the OIZ, Hayati Aslan stated that they are continuing their R&D studies within the Teknopark at Mersin University and said that they are planning investment for production in the Mersin Tarsus Organized Industrial Zone expansion area. Stating that they are planning to realize the first construction in July of a year, Aslan said, “Our primary target market is some provinces and districts in the Mediterranean, such as the Aegean, Marmara and Tarsus, where olive production is intense. Then, we are planning to export the Olive color selector to Mediterranean countries such as Greece, Italy and North Africa. Stating that the project will be implemented with an estimated investment of 500 thousand TL, Hayati Aslan said that when they started production, they would receive marketing support from the Mersin Chamber of Commerce and Industry.

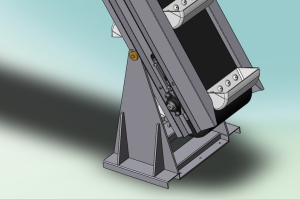

Olive color sorting machine

It is a single-core fruit that cannot be eaten as it is collected from an olive branch. This is caused by a phenolic substance called “oleuropein”, which gives the olive its bitter taste by being found only in olives all the fruits in the world. Oleuropein is also considered a very important substance for human health. (Olive color pick machine) It is said by the researchers that the amount remaining in the olive is sufficient for human health, even if this substance is sent out of the olive’s body or broken into other things while making table olives. They are substances that affect positive. It is a food that contains 70 water, 15-30% fat, 2-6% sugar, 1-3% protein, 1-4% mineral products and 1-5% fiber. Along with these, it contains phenolic components called minor components, organic acids, pectins, color substances, vitamins and some minerals in quantities that can be said to be important for human life. (Olive color pick machine) Table olives are regarded as a nutritional value because of all the following substances. While it contains a strong amount of sugar such as sugar, 1.5% fat, it is 2-6% for sugar and 15-30% for oil, respectively. (Olive color pick machine) Table olive processing skills are technologies that enable the bitterness of olives to be eliminated and made edible by humans. The olives that are processed in this way and become edible by removing their bitterness are also called “table olives.” Some of the important table olives growing in our country are: Gemlik, Ayvalık, Memecik, Tomat, Uslu, Donkey Olive, Yamalak Yellow, Erkence, Mameli, Yellow Ulak, Halhalı , Edincik Water, Rabbit Heart etc. While most of these types of Gemlik and Domat are processed for table, an insignificant portion goes to oil. Other types are processed both for table and for oil. In green olive processing, olives are made edible with both natural and chemical applications.

In our country, the technology of making olive with boots is applied more for Ayvalık and Domat varieties. (Olive color selection machine) Drawing olive production parts;

Output: Harvest time and method of olives are very important in table olive technology. Olives must be collected manually. Harvest time is determined according to the processing method. In the processing of boots olive, Ayvalık type olives are harvested when the color starts to turn from green to yellow and pink or slightly black. (Olive color sorting machine) For tomato type, it is more appropriate to make the time when the color turns from green to straw yellow. Transportation: The harvested olives are not stopped in the sun and are transported in twenty-five kg plastic baskets. They are separated, then they are passed through the sorting band to separate dents, bruises and bruises. Drawing: After being washed with pure water to be extracted, the drawing process is applied. In the drawing process, one or more olives are drawn laterally or longitudinally.

Flavoring: Scratched olives are taken into containers. The perforated lid is closed on it and the brine containing 2% salt and 0.2% citric acid (lemon salt) is given to it. It is filled with brine to the top of the lid 10-15 cm. (Olive color selection machine) Once a week, the water is poured and the same amount of fresh brine is given and this treatment is done 5-6 times. In the 5th and 6th repetitions, it is decided whether the sweetening muamelat is finished or not by checking the taste of the olive. If the olives have reached the taste and breath of boot olive, they are finally given to the sweetening process and they are stored and matured.

Preservation and Fermentation: The flavored olives are preserved with brine containing 7% salt and 0.5-0.7% citric acid. It is released to the market at any time after fermentation and maturation treatment for 1-2 months. (Olive color selection machine) If it is to be preserved for a longer time, the salt amount can be increased to 10% and the acid ratio can be increased to 1-1.2%. Packaging: Glass jars are frequently used together with tin and plastic boxes in the packaging of the sweetened and maturing olives. First, a brine containing 5 percent salt and 1-1.5 percent citric acid is prepared. After pouring olives into the containers, brine is given. A good grade of olive oil is added to cover the surface of the box.