This scheme soybean processing allows you to complete all soybean processing steps soybean oil and oilcake making machines, namely, sequentially separate soybean husks, extrude the core of soybean, production full-fat soybean and press the oil from full-fat soya, cool the soybean cake with oil content 7 … 8%

Soybean processing goal/benefit:

Processing in animal feed production allows to obtain products with a high content of absorbable functional protein from soybeans.

Soybeans contain from 25 to 35% of protein. Soybean oil cake production allows to obtain 39 … 42% of protein. Soybean meal production is characterized by 40 … 48% soybean protein content. The soybean oil protein isolate contains up to 70% protein.

Soybeans contain trypsin inhibitors, which are anti-nutritional substances that prevent the absorption of soy protein when eaten.

The brief pressure treatment at high temperature in the soybean extruder reduces the content of trypsin inhibitors.

The own processing of soybeans guarantees food consumers the safety of protein conditions, an acceptable level of trypsin inhibitors and the absence of non-protein impurities.

The increase in the mass fraction of protein in soybean products is due to the extraction of other nonprotein substances from beans.

Extracting soybean oil is one of them.

Soybeans contain from 15 to 25% of fats.

How to process soybeans:

There are two main methods how to processing soya beans, namely extraction and mechanical processing.

Extraction processing involves the use of chemical reactions to extract fats and carbohydrates from soybeans.

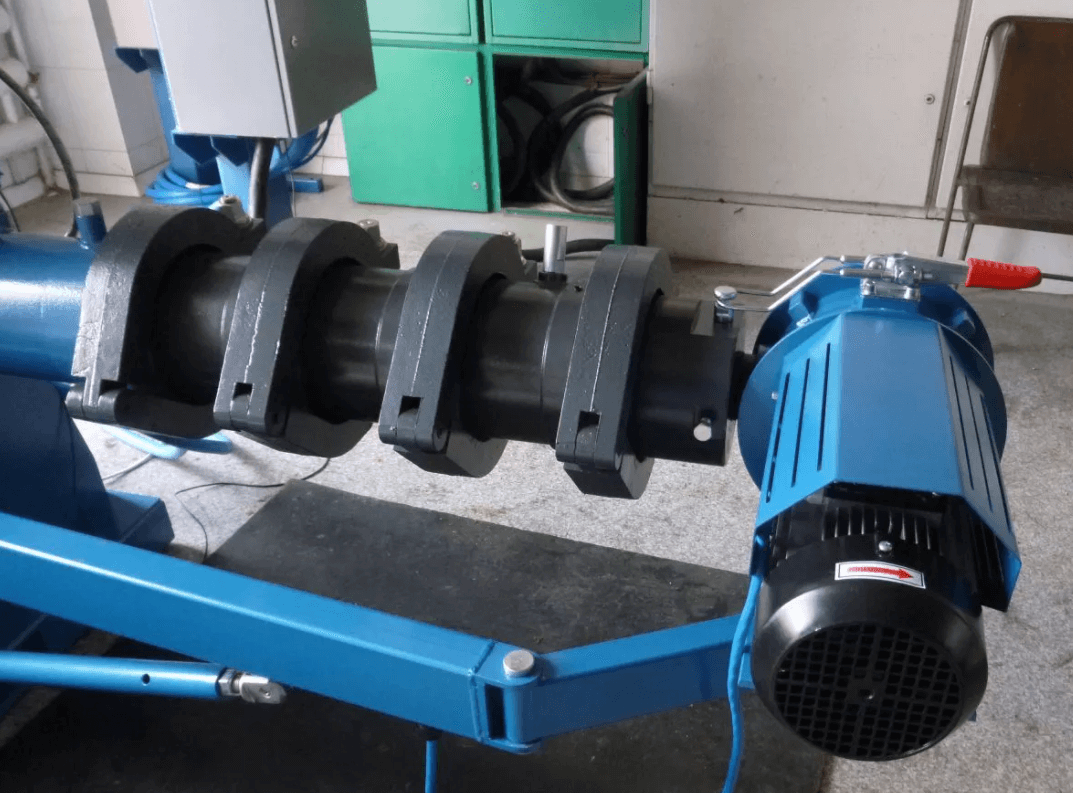

Mechanical processing includes crushing, sorting, grinding, compressing and high temperature processing.

Both methods can be combined.

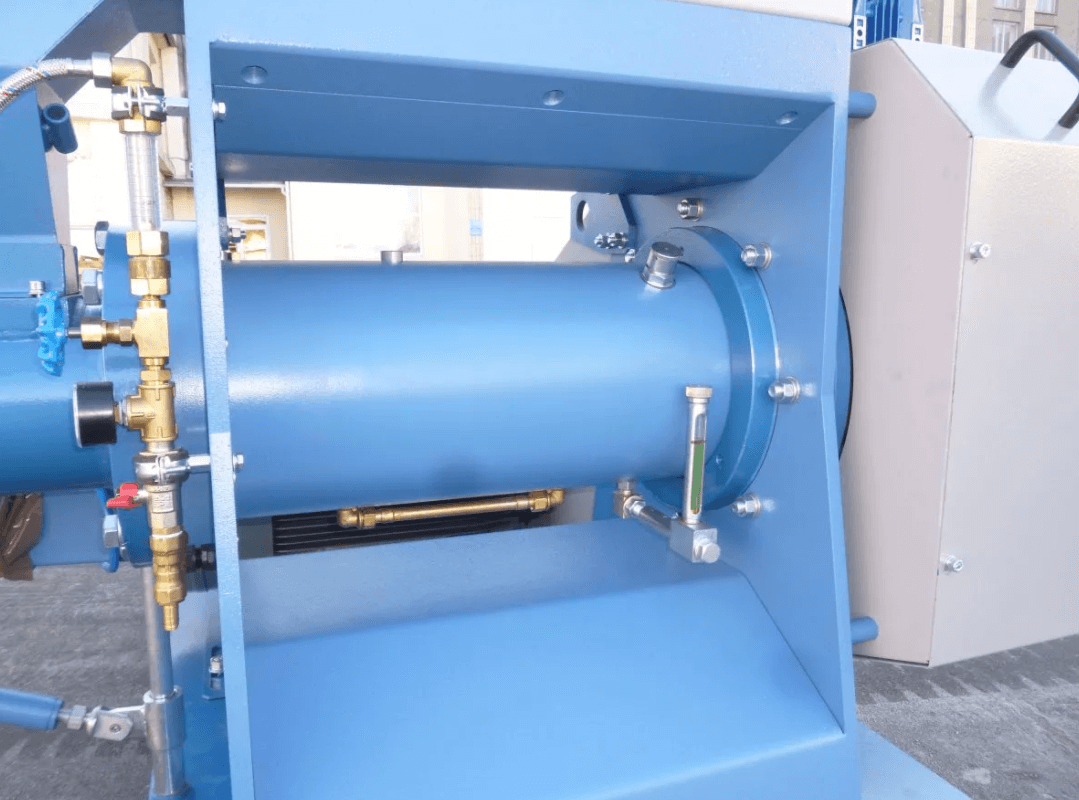

For example, initially 8 … 17% of oil is mechanically pressed to get a soybean cake with oil content of 7 … 8%, and then soybean meal with oil content of 0.5 … 2% is produced in the extraction reactors.

What do you get using our equipment:

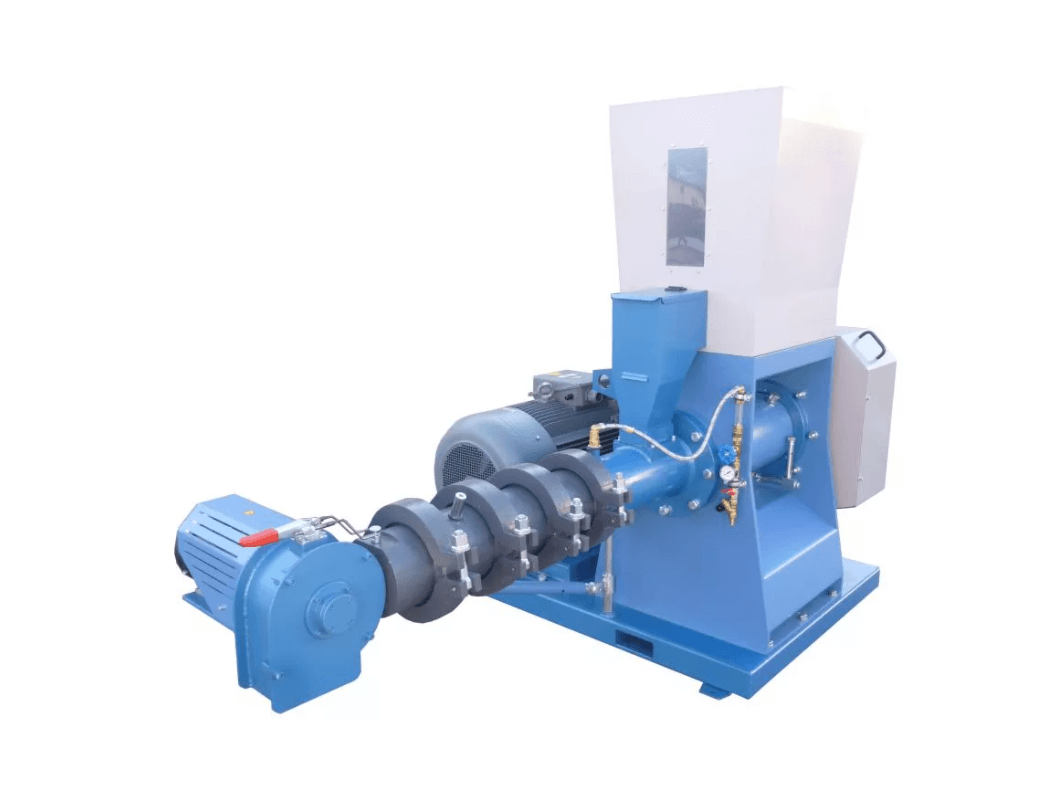

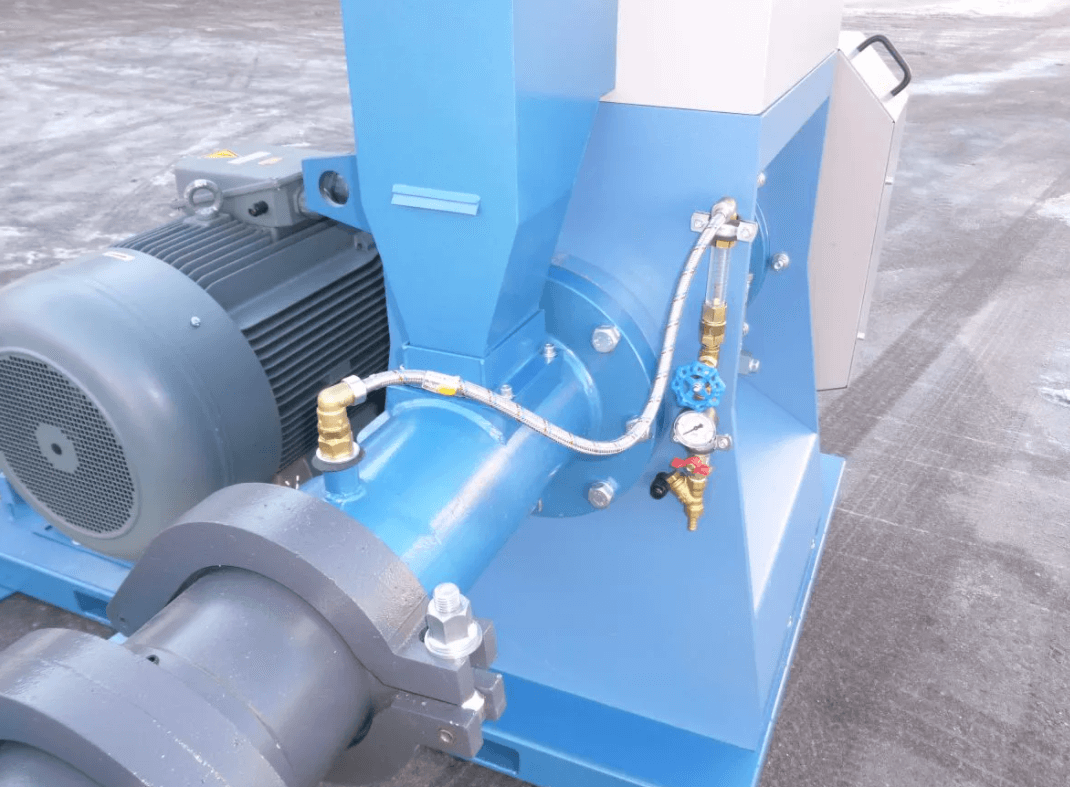

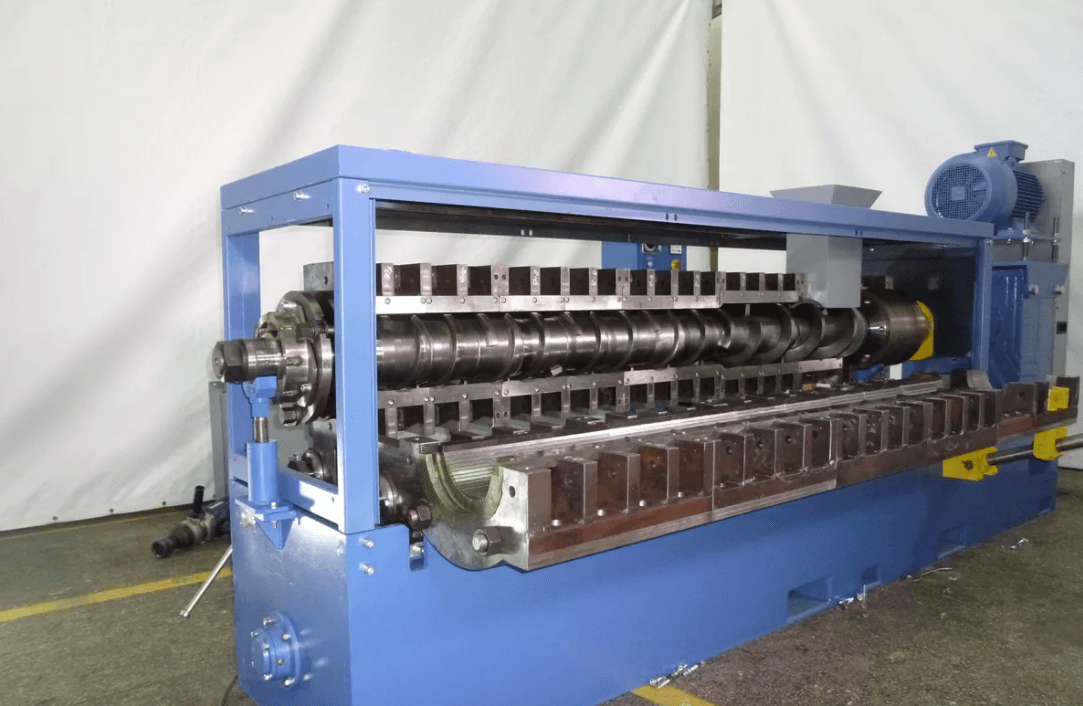

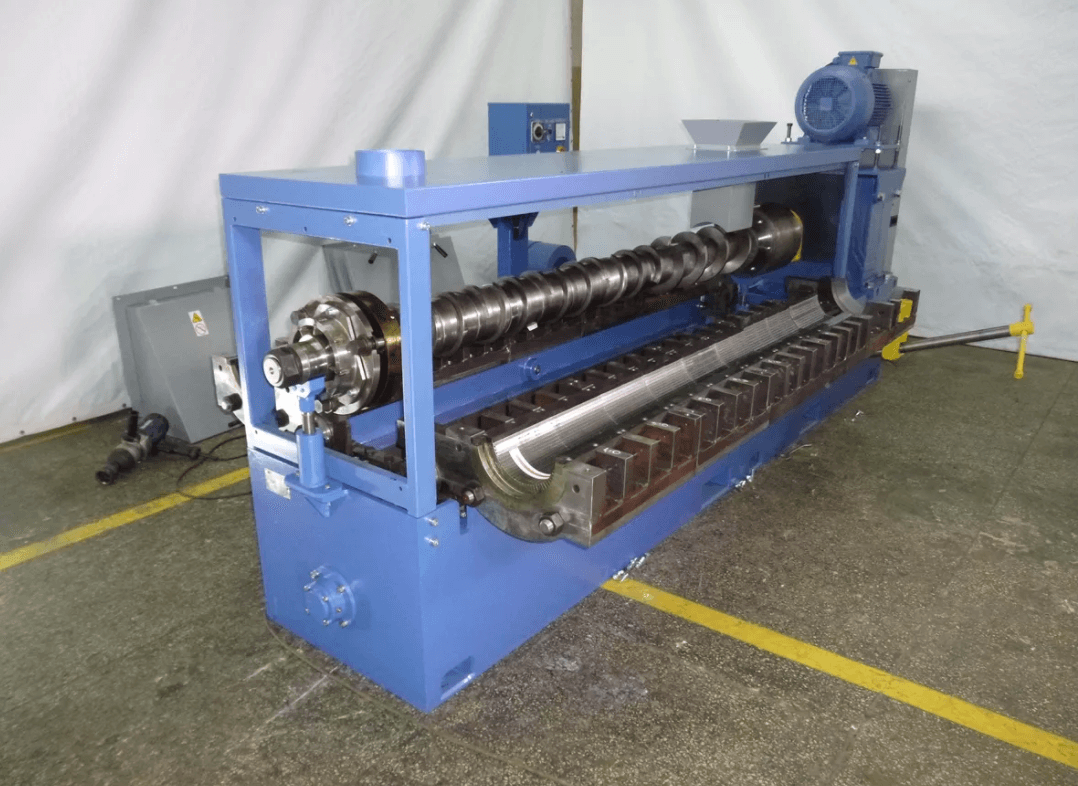

We manufacture equipment and complete production lines for soybean mechanical processing that is essential for soybean processing plants.

Check out the scheme according to which we complete soybean oil and cake lines under production conditions of our customers.

This scheme allows you to complete all soybean processing steps, namely, sequentially separate soybean husks, extrude the core of soybean, production full-fat soybean and press the oil from full-fat soya, cool the soybean cake with oil content 7 … 8%

Produced soybean cake can be used as raw material for soya chunks or soy protein snacks manufacturing process

From what raw material:

For efficient soybean oil extraction process, the following requirements should be met:

Optimal soybean moisture content (for maximum oil yield): 8 … 9%.

To optimize the extrusion and pressing processes, the soybean is dried immediately before processing.

Light and heavy impurities are removed

If necessary, it is divided into fractions

Content of impurities does not exceed 3%

Processing cost:

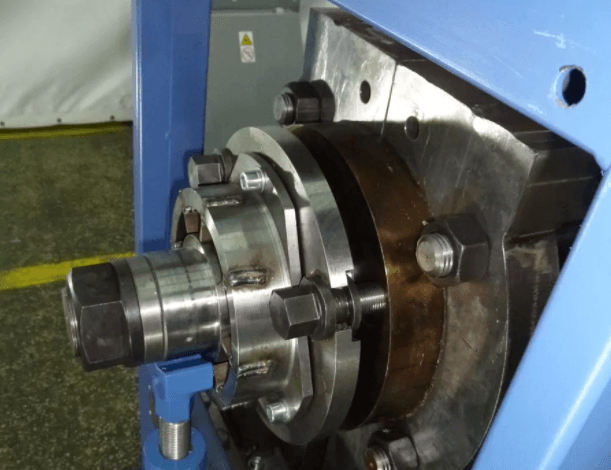

When processing soybeans, the main expenses are related to electricity, wages for at least 2 employees, fast-used parts of the extruder and the press

Project cost – soybean processing into oil cake and oil:

To calculate the cost of your project, we offer to contact our experts, as there are many features affecting soyabean oil plant cost, that are related to raw materials, product requirements, logistics, production facilities, storage conditions, availability of energy sources, etc. so that you’ll get idea on soya bean oil plant for sale.

The main costs that will make up the total soyabean plant cost are as follows:

-

production equipment set

-

transport equipment set

-

power connection

-

preparation of production facilities

-

preparation of premises for raw materials storage, cake storage and soybean oil storage

-

control automation

-

laboratory for the determination of fat and protein content, humidity, urease activity

Our technology:

USED FOR:

-

soybean processing

-

soybean cake production with oil content of up to 8%

-

soybean oil production process

Soybean processing technology scheme:

soybeans – soybean peeling – soybean extruding – mechanical oil pressing – cake cooling – solid residue deposition in soybean oil

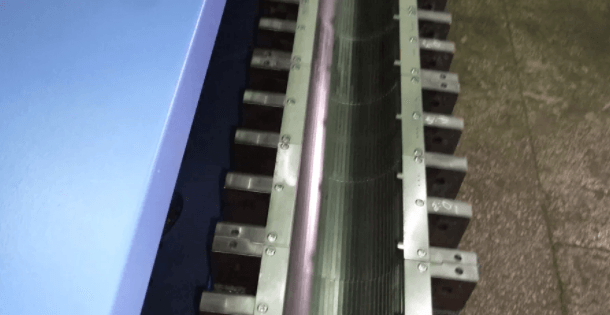

Our soybean processing equipment and soybean meal production technology reduces oil content to 7 … 8% in one single pass